oxide removal ( pickling ) rate generally decreases when the metals concentration increases. The bath must be dumped when the oxide scale is no longer being adequately removed.

在金属精加工行业常用强无机酸(硫酸,硝酸,盐酸)来去除表面的氧化物以减少对后续生产操作的影响。在很大程度上这些氧化物是被酸溶解的,并且随着溶解的金属浓度的增加游离酸的浓度也相应减少。虽然新的酸可被加入到溶液中以弥补这一点,但是当金属浓度增加的时候,氧化物去除率(酸洗)通常会降低。当氧化皮不再被充分去除的时候,这些酸液就必须被倒掉。

This method of operation can cause productivity related problems. Freshly formulated pickling baths containing very low levels of dissolved ironare very aggressive and can cause over pickling. Material of substandard quality can also be produced as the bath approaches the spent condition.Rework may be necessary to prevent problems with subsequent surface treatment processes.

这种操作方法会引起生产率有关的问题。含有溶解的铁含量很低的新配制的酸洗浴是非常强劲的,并可能导致过度酸洗。由于酸洗而接近报废的质量不合格的材料也可能会产生。返工可能是必要的,以防止出现后续的表面处理工艺问题。

In addition, spent pickle liquors can contain large amounts of unused or "free" acid. Free acid in a spent pickle bath represents a loss of valuablechemicals and a waste treatment liability. Continuous purification of pickle liquors can, therefore, offer several benefits to steelmakers:

- uniform product quality with reduced rework

- increased average pickling speed

- reduced chemical consumption

- reduced waste handling requirements

此外,用废了的酸洗液也包含了大量的未使用的或“游离”酸。用废了的酸洗液中的游离酸代表了有价值的化学品和废物处理的责任双方面的的亏损。因此酸洗液的连续纯化可以提供为钢铁生产商带来如下优势:

- 降低返工率,统一产品质量

- 增加平均的酸洗速度

- 减少化学品消耗

- 减少废物处理要求

2.0 The APU Process/酸纯化系统工艺

Certain ion exchange (1x1 resins, similar to those used in water softeners and water deionizers, have the ability to absorb strong acids while excluding metal salts of these acids. The acids can readily be desorbed from the resin beads with a water wash. While this phenomena, known as "acid retardation", was observed by researchers in the early sixties it was not successfully commercialized at that time. This was likely due to the limitations of conventional IX equipment design. While the acid retardation work was underway, a novel ion exchange process was being developed at the University of Toronto. This totally new approach to ion exchange

某些离子交换(有吸附强酸而排除这些酸的金属盐的能力的特殊树脂)。并且这些酸可以很容易地用水从树脂粒上冲洗出来。虽然这现象,被称为“酸迟滞” ,研究人员在六十年代初已经发现了这种现象,但是它在那时候并没有被成功的商业化,这很可能是由于传统的IX 设备设计的局限性。当今酸迟滞工作正在进行中,多伦多大学发明了一种新的离子交换工艺。这种全新的方法近似于离子交换

- embodied several unique design features:

- Fine mesh resin beads ..... to increase the surface area per cubic foot and improve reaction kinetics.

- Short resin beds .. . . reducing pressure drop and equipment size

- Fixed resin beds .... to minimize intermixing and dilution of feed and regenerant phases.

- Countercurrent flows .... of feed and regenerant steps to maximize chemical efficiency.

体现了一些独特的设计特点:

- 细网树脂粒.....增加每立方英尺的表面积,提高反应动力学。

- 矮树脂床.....减少压力降和设备尺寸

- 固定树脂床....尽量减少相互混合和稀释进料和再生时间。

- 逆流进水....以最大限度地提高进料和再生步骤的化学效率。

In 1975 a program was initiated to apply the process to acid retardation. The program was a success and the first acid retardation system using this technology was installed in 1977 for the purification of sulphuric acid anodizing solutions. Since that time over 150 similar systems have been installed.

1975 年,一个适用于酸迟滞工艺的项目被启动。该项目是成功的,在1977 年完成安装,这是第一个使用这种技术的酸迟滞系统,用来净化铝阳极系统中的硫酸溶液。采用这种技术的第一酸迟缓系统为硫酸阳极氧化溶液的净化安装于1977 年。自那时以来,已经有超过150个相似的系统安装完毕。

3.0 Basic System Design/基础系统设计

In many pickling operations, the bath is formulated, worked, adjusted for free acid content as required until the dissolved metals reach a critical level, and dumped. An Acid Purification System is normally designed to hold the dissolved metal levels at a preferred operating level, typically 50 - 60% of normal dump concentration. Free acid concentration can be maintained at whatever level is required to provide the necessary pickling rate.

An Acid Purification System process is shown in Figure 1. There are three basic steps in the System including:

在许多酸洗操作中,酸洗液配置,工作,根据需要调整游离酸含量直到溶解的金属达到一个临界水平,并且储存。一个酸纯化系统通常设计为保持溶解金属水平在一个最佳的操作水平,一般为正常转储浓度的50-60%。游离酸的浓度可以保持在要求的任何水平,以提供必要的酸洗速度。酸洗系统的工艺过程如图1 所示。系统包括三个基本步骤:

- Bath cooling (if required)/冷却(根据需要)

- Bath filtration/过滤

- Acid Absorption/酸吸收

Bath cooling/溶液冷却

Bath cooling is necessary where oxidizers such as nitric acid or hydrogen peroxide are present. While sulphuric and hydrochloric acids can be treated at temperatures up to 80 ℃, the presence of oxidizers necessitates that the feed be cooled to about 32 ℃. City water is normally used for cooling. A variety of cooler designs are available depending on the particular requirements of the system. The water may be used for regeneration of the absorption resin and rinsing on the pickle line.

当氧化剂有硝酸或过氧化氢存在时,一般要求溶液冷却。硫酸和盐酸在可以在温度高达80℃时处理,但是有氧化剂存在时,进料必须被冷却到大约32 ℃。通常是用市政供水冷却。可根据系统的特殊要求设计各种冷却器。这个水可用于吸附树脂的再生和酸洗生产线的漂洗。

图1. 典型的酸纯化系统工艺

酸洗槽酸洗漂洗槽

进水

生产工艺储水槽 水过滤器 酸过滤器 生产工艺补给槽

废液

酸纯化系统

纯化产物

a) Bath filtration/过滤

Proper filtration of the pickling acid and the regeneration water is necessary to minimize pressure drop across the absorption resin bed.

酸洗酸和再生水的适当的过滤是必要的,可以尽量减少通过吸附树脂床的压降。

Pickling acid solution is filtered in a multimedia pressure filter. A backup cartridge filter is also used. The amount of solids to be removed will depend on what alloy has been pickled and how much scale has been removed, however it should be noted that the solids load is usually much lower with the purification system in operation. This is because dissolved metal concentrations are kept below their solubility limit and crystallization of metal salts does not take place.

酸洗酸溶液通过多介质压力过滤器过滤。也使用备份滤芯过滤器。固体被去除的量将取决于已被酸洗的合金和被去除的标准,然而应该指出的是,净化系统在操作中的固体负载通常是很低的。这是因为溶解的金属浓度低于其溶解度极限并且金属盐的结晶不会发生。

A monitor on the filter checks the differential pressure between the inlet and the outlet and indicates when a backwash is required. A combination of water and compressed air is used to backwash and scour the media. The backwash sequence begins with an air blow down to exhaust the entrained pickle liquor to the surge tank. The media is then fluidized with a combination of air and water to remove trapped solids. The waste water from the backwash may contain small amounts of acid and should be treated with rinse waters from the pickle line.

在过滤器上的监视器检查该入口与出口之间的压力差,并指出是否需要反冲洗。用水和压缩空气的组合来进行反洗和擦洗介质。反冲洗顺序是先用空气排污开始,排出夹带酸洗废液到缓冲罐中。介质通过流动的空气和水除去夹带的固体。反洗废水中可能含有少量的酸,并用酸洗线的漂洗水来进行处理。

Water for regeneration of the absorption resin is filtered in a multi-media filter similar to the one used for the feed acid. With this filter no special air blowdown or scouring is required.

用于再生吸附树脂的水,用一个类似于过滤进料酸的多介质过滤器进行过滤。但这个过滤器不需要特殊的空气吹净或冲刷。

b) Acid Absorption/酸吸附

Acid absorption takes place in a skid mounted device called an Acid Purification Unit or APU . The APU consists of a container or "bed" of absorption resin, process valves and controllers. It is the heart of the System. Figure 3 is a photograph of an Acid Purification System for sulphuric acid service.

酸的吸收在酸净化系统(APU)撬装设备中进行。APU 由吸附树脂的”床”或者容器,工艺阀门和控制器组成。它是系统的核心。图3是用于回收硫酸的酸纯化系统的照片。

The resin bed is a cylindrical vessel 30 - 60 cm (12" - 24") in height. Bed diameter is dependent upon the feed flow and typically varies between 15 - 180 cm (6'' and 72").

树脂床是一个高30- 60 厘米(12" - 24")的圆柱形容器。床体的直径取决于于进料的流量,通常在15- 180 厘米(6 '-72“)之间变化。

The APU works on a very simple two- step cycle. During the first part of the cycle, the upstroke, filtered acid is pumped up through the resin bed and free acid is absorbed by the resin beads. Dissolved metals pass through the unit unhindered. This step continues until the resin bed has been fully loaded with acid.

APU 以一个非常简单的两步循环模式工作。循环的第一步是上冲程,过滤后的酸通过泵流过树脂床,游离酸被树脂粒吸附。溶解的金属则畅通无阻的流出树脂床。这一步一直持续到树脂床吸附酸饱和。

Byproduct solution flowing from the unit will contain dissolved metals and a small amount of dissolved acid. In some cases the byproduct may contain recoverable chemicals, however, in most cases it must be neutralized and clarified prior to discharge. The suitability of the plant's effluent treatment system should be checked to ensure adequate capacity is available in neutralization tanks and filters.

通过本系统的副产物溶液将包含溶解金属和少量溶解酸。在某些情况下,副产物可能含有可收回的化学物质,但是,在大多数情况下,它必须被中和和处理后排放。应该检查工厂废水处理系统的适用性以确保中和池和过滤器有足够的处理能力。

After the resin bed has been loaded with acid, filtered water is pumped down through the bed during the "downstroke" part of the cycle. The water desorbs the acid from the resin at a Concentration suitable for recycle back to the pickle tank. This step continues until the bed has been fully regenerated.

树脂床吸附完酸后,循环的第二步是“下冲程”,过滤后的水通过泵从上向下流经树脂床。按照适合循环到酸洗槽的酸的浓度,用水把酸从树脂上脱附下来。这个步骤一直持续到床已经完全再生。

At the beginning of each of these steps a void solution can be recycled. In the case of the upstroke step this void is essentially just the water that was left in the bed from the preceeding cycle. The void during the downstroke is feed acid that can either be mixed with the purified acid or returned to the feed tank.

在每一个步骤的开始,产生的空白液可以循环使用。在上冲程步骤中,空白液实际上只是上一个周期中留在树脂床中的水。在下冲程过程中,空白液是和纯酸混合的进料酸,或返回到进料罐中。

The unit's operation is regulated by a flow totalizer that is coupled to a programmable controller. It is worthy to note that in all applications, acid is pumped up through the bed and water is pumped down through the bed. This utilizes the density differences of the two solutions to maintain a stable interface between the acid and water, approaching plug flow through the resin bed. Solution intermixing and dilution is minimized.

本装置的操作是由耦合了一个流量计的可编程序控制器来管理的。值得一提的是,在所有应用中,酸被泵向上穿过床和水被泵向下通过床。这利用了两种溶液的密度差,以保持酸和水之间形成稳定的界面,通过树脂床接近活塞流。以使溶液混杂和稀释的最小化。

图3 APU 工艺步骤

4.0 Applications in the Steel Industry/在钢铁行业的应用

The three pickling solutions used most frequently in the steel industry are based on sulphuric, hydrochloric or nitric acids.

最常用在钢铁行业的三种酸洗液是硫酸,盐酸和硝酸。

4 .1 Stainless Steel (Mixed Acid) pickling/不锈钢酸洗(混酸)

Mixtures of nitric and hydrofluoric acids are used to remove scale from most grades of stainless steel. Generally, these baths are formulated with 10 -15 percent by weight nitric acid and 1-4 percent by weight hydrofluoric acid, depending on the alloy to be created. Bath temperatures are maintained at 55-65℃. During the pickling process iron, chromium and nickel are dissolved in to the acid. Concentrated nitric and hydrofluoric acid must be added regularly to maintain free acid levels, however, when the metals content of the solution exceeds 5 - 6% w/w, metal salts begin to crystallize out of solution and the bath must be dumped. Frequently, manual labour must be used to remove these sediment from the tank.

大多数级别的不锈钢用硝酸和氢氟酸的混合物来去除表面层垢。通常,这些酸液的配方是根据要处理的合金,加入10-15%的硝酸(重量)和1-4%氢氟酸(重量)。酸洗温度保持在55- 65℃。在酸洗过程中,铁铬镍被溶解在酸液中。必须定期添加浓硝酸和氢氟酸以保持游离酸的水平,然而,当溶液中金属含量超过5 - 6%w/w 时,金属盐开始结晶并从溶液中析出,此时该酸洗液必须更换。通常情况下,必须用手工作业来从酸洗槽中去除这些沉积物。

With the APU System, the total dissolved metals concentration can be continuously maintained in the range of 2-4% w/w. This enables the solution

to be used indefinitely. Typical results using the APU on mixed acid service are given in Table 1.

通过APU 系统,总溶解金属浓度可连续地保持在2-4%w / w 的范围内。这使得溶液能够无限期使用。如下表1 所示为混酸中使用APU 系统服务的结果。

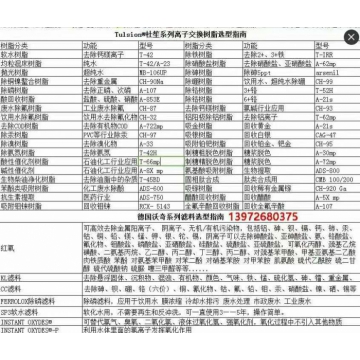

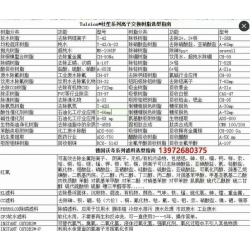

Table 1: APU Results - Nitric / Hydrofluoric Service/表1. APU 结果-硝酸/氢氟酸系统

Component/成分Feed/进料Product/产品Waste/浪费% Loss/损失

Nitric acid/硝酸(g/L) 120 114 5 5

Hydrofluoric acid /氢氟酸(g/L) 30 24 5 20

Iron/铁(g/L) 30 9 18 70

Chromium /铬+ Nickel /镍(g/L) 10 3 6 70

Relative Flow/相对流量1 1 1.2

The concentrations of nitric and hydrofluoric acid shown above are free acid concentrations. The absorption process has been observed to be more efficient with highly dissociated (strong) acids. As the hydrofluoric acid is a weaker acid than the nitric, the recovery efficiency is lower. The installed cost of the APU System is dependant upon the amount of dissolved metals that must be removed from the pickle liquor and can vary between $75,000 and $500,000. These capital costs can be recovered very quickly due to value of the acids involved.

上面所示的硝酸和氢氟酸的浓度是游离酸的浓度。吸收过程中可以观察到对于高离解的(强)酸更有效。因为氢氟酸是比硝酸要弱的酸,因此回收效率较低。此APU 系统的安装成本取决于必须从酸洗溶液中去除的溶解金属的量,大约在75000 美元至500,000 美元。这些资本成本可以很快的通过回收的酸的价值中收回。

An Economic evaluation is presented for the APU System on mixed acid service in Table 2. The evaluation is based on the following conditions:

Spent bath flow rate: 1500 L/hour (400 USGPH)

应用在混酸中的APU 系统的经济评价如表2 所示。该评估是基于下列条件:废酸流速:1500 升/小时( 400 USGPH )

Spent bath composition/废酸成分:

100 g/L HNO3 (9% w/w)

20 g/L HF (1.8% w/w)

40 g/L Fe (3.6% w/w)

Plant operation/设备运行: 6000 hours per year/6000 小时/年

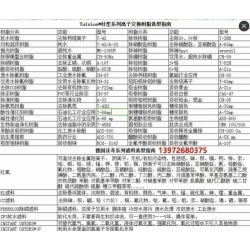

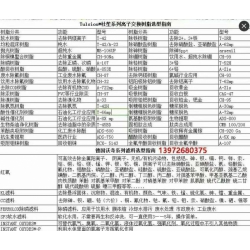

Table 2: Economic evaluation on Mixed Acid Service/表2: 关于混酸系统的经济评价

NOTES/注意:

A) All costs are expressed in U.S. Dollars. All weights are expressed in metric tonnes (2200 lbs).

所有费用均以美元计算。所有重量均以吨计算(2200 磅)。

B) Chemical costs based on prevailing rates as reported in Chemical Marketing Reporter ( 7 / 8 7 ) .

There is a lesser reduction in hydrofluoric acid purchases than might be expected from the operating data presented in Table 1. It has been assumed for the sake of the analysis that both iron and chromium metals are tri-valent and present in solution as complex fluoride salts. Despite this, the chemical and treatment cost savings can readily justify the capital expense. The evaluation does not attempt to quantify benefits associated with uniform pickling rates (reduced rework) and composition (prevention of salt crystallization and tank cleaning) although these can be very significant.

化学品成本根据当时报告的化学品市场报价。这里氢氟酸的购买量比表1 中的所预计的操作数据有所减少。这是为了分析而做的假定,铁和铬在复杂氟化盐中以3 价形式存在。尽管如此,化学品和处理成本的节约可以很容易地证明了资本支出。评价没有尝试去计算统一的酸洗速率(降低返工),沉淀物(预防盐结晶和罐体清洁)产生而带来的利益,尽管这些可能是非常显著的益处。

Cost Component /成本构成Annual Cost /年度成本($/year)

Simple Neutralization/简单中和APU System/APU 系统

70% HNO3 $ 150 per tonne/吨$192,900 $ 13,800

70% HF $ 950 per tonne/吨$769,500 $592,800

Lime(石灰石) $ 50 per tonne/吨$ 86,700 $46,500

45% Cake Haulage(沉淀) $ 40 per tonne/吨$173,500 $144,400

Labor(人工) $15 per hour/小时$ 30,000

Replacement parts/更换配件$12,000

Utilities/程序$3,000

Total Operating costs/总成本$1,222,600 $ 842,500

Savings compared to Simple Neutralization/节约$ 380,100

Estimated Capital Costs/估计资本成本$300,000

Payback period/投资回收期(year 年) 0.79

4 .2 Hydrochloric Acid Pickling/盐酸酸洗

Hydrochloric acid is commonly used for pickling of mild steel on batch and continuous lines. Baths are made up with a free acid concentration of 10-15 percent by weight and can be operated between 20 and 80 degrees celcius. The baths are dumped when the dissolved iron level reaches 8 - 10% by weight. It is possible to reduce free acid levels to less than 5% as the bath reaches a spent condition. Spent acid can be contract hauled, neutralized with lime or, in some cases, used to produce ferric chloride.

盐酸通常用于低碳钢的连续酸洗线。酸洗液体是由10-15%的游离酸(按重量)组成,在20-80℃之间进行操作。当溶解铁的含量达到8-10%(按重量)时,酸洗液需要更换。当酸洗液变成废酸时,它的游离酸水平可能降低到5%。废酸按照约定运走,用石灰中和,或在某些情况下用于生产氯化铁。

Continuous strip lines frequently operate three or four pickle tanks in series with the flow of acid running continuously between tanks. This design allows spent pickle liquor to be continuously withdrawn at very low free acid levels. In order to achieve the high pickling rates required in these lines, elevated temperatures must be used. This can lead to problems with acid vapour losses. with the APU System it is possible to reduce the solution temperature by operating the pickle liquor at higher free acid concentrations. This can be done economically since the APU System recovers virtually all of the free acid.

连续酸洗线频繁的操作三四个连续的酸洗槽,他们两两之间的酸洗液相互流动。这样的设计允许酸洗废液在非常低的游离酸含量下连续排出。为了在这些酸洗线上实现所要求的高效酸洗,就必须要升高温度。这可能会导致的问题是酸蒸气损失。使用APU 系统,可以通过处理酸洗废液以使游离酸浓度在较高的水平来降低溶液的温度。这样做是非常经济的,因为APU 系统恢复几乎所有的游离酸。

In batch pickling operations the level of free acid in the spent liquor can be substantial. The APU can be used to continuously remove iron from the bath thus eliminating bath dumps. This reduces the loss of free acid and the attendant treatment requirements. In addition, by allowing the economical use of higher free acid concentrations and lower dissolved iron concentrations, pickling speeds can be increased. The elimination of lost production time due to bath dumping and re-formulation is another benefit of continuous purification. Typical results for the APU System on hydrochloric acid service are given in Table 3.

在批处理酸洗作业中废液中的游离酸的水平可能很高。APU 可用于连续地从酸洗液中去除铁离子,从而避免更换酸洗液。这减少了游离酸和所伴随的处理的损失。此外,通过经济地使用高浓度的游离酸和较低的溶解铁浓度,可以提高酸洗速度。并且没有浪费生产时间去更换酸洗液,这是另一个好处。APU 系统在盐酸酸洗行业的表现,如表3 。

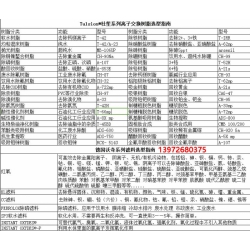

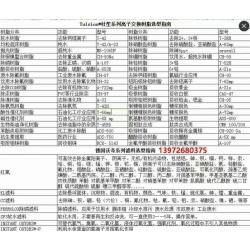

Table 3: APU Results - Hydrochloric Acid Service

Component /成分Feed/进水Product/产品Waste/浪费% Loss/损失

Hydrofluoric acid /盐酸(g/L) 150 153 8.6 4

Iron/铁(g/L) 50 32 29 40

Relative Flow/相对流量1 0.94 0.7

The product is returned from the APU in a slightly concentrated state. Consideration must still be paid to the water balance in the pickle tank, particularly since commercial grade hydrochloric acid is a relatively weak (32% w/w) solution. If steam spargers are used for bath heating, difficulties may be encountered with the dilution caused by the condensed steam. Out-of-line heating systems using shell and tube heat exchangers are preferred to maximize the acid recovery.

从APU 系统得到的产物有轻微的浓缩。必须注意的是酸洗槽的给水量平衡,很明显的原因是商业级盐酸是一种相对较弱(32%W/W)的溶液。如果使用蒸汽喷淋器来进行酸洗加热,遇到的难点可能是浓缩的蒸汽稀释溶液。可以首选管壳式热交换器的外部加热系统,可以最大限度地回收酸。

As previously discussed, other productivity related benefits have not been considered. In addition to quality related benefits, the APU System can allow higher free acid concentrations to be used economically. This may permit lower bath temperatures to be used. In addition to energy savings, lower temperatures lead to a reduction in HC1 vapor losses and the attendant treatment requirements.

正如前面所讨论的,其他生产相关的优势都没有被考虑。除了质量有关的优势外, APU 系统可以允许经济地使用较高浓度的游离酸。这可以允许在较低的酸洗温度下使用。除了节约能源,降低温度导致盐酸蒸气损失外,随之而来的是减少处理成本。

4.3 Sulphuric Acid Pickling/硫酸酸洗

Sulphuric acid is most commonly used in batch pickling operations although, there are still some continuous sulphuric pickling lines in use. Generally, at least 10% w/w sulphuric acid must be maintained in the pickling acid to ensure minimum pickling rates. The acid becomes spent when the dissolved iron level reaches 6 - 8% by weight. At higher levels the iron will crystallize out of solution. Care must be taken not to allow either the free acid level, or the bath temperature, to get too high as this will depress the solubility of the ferrous sulphate. In addition to the controlconsiderations required with sulphuric acid, the spent bath can be difficult to treat. Dosing with lime generates large amounts of calcium sulphate(gypsum) sludge.

虽然硫酸最常见的用于批量酸洗操作中,但仍然有一些连续酸洗线在用。通常,在酸洗酸中至少保持10%w/w 的硫酸,以确保最小的酸洗速度。当溶解铁达到6-8%(重量)时,酸将失效。如果继续升高,铁将从溶液中结晶出来。特别注意的是,不能提高游离酸的浓度或者酸洗温度,因为这将压制硫酸亚铁的溶解度。除了考虑用硫酸所需的控制外,废酸也是非常难处理的。用石灰加药会产生大量的硫酸钙(石膏)污泥。

Use of the APU on sulphuric acid pickling solutions can overcome these disadvantages. Continuous bath purification ensures that dissolved ironconcentrations don't exceed solubility levels.

对硫酸酸洗液使用APU 系统可以克服这些缺点。连续酸洗净化确保溶解铁浓度不超过溶解度的水平。

Since the APU recovers free ( or unused ) acid in solution, higher sulphuric acid concentrations can be used economically. This can lead tosignificantly increased productivity levels. Typical results are given below.

因为APU 可以恢复溶液中的游离酸,可以经济的使用较高浓度的硫酸。这可能会显著的提高生产力水平。测试结果如下:

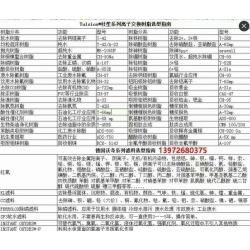

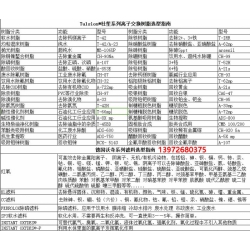

Table 5: APU Results - Sulphuric Acid Service/硫酸酸洗的APU 结果

Component /成分Feed/进料Product/产品Waste/浪费% Loss/损失

Sulphuric acid /硫酸(g/L) 150 138 10 8

Iron/铁(g/L) 70 26 40 65

Temperature/温度(℃) 80 76 19 5

Relative Flow /相对流量1 1 1.15

It is worth noting that the APU System recovers most of the heat in the feedstock.

值得注意的是,该APU 系统回收了进料中的大部分热量。

The APU process does not remove the ferrous sulphate in a recoverable form and magnesium hydroxide treatment is recommended. While this results in the generation of a considerable amount of ferrous hydroxide sludge, the filter cake is generally considered to be non-hazardous and canbe used as a landfill.

APU 工艺不会去除可回收形式的硫酸亚铁,建议用氢氧化镁处理。尽管这导致了相当数量的氢氧化亚铁淤渣的产生,但是滤饼普遍认为是无害的并且可以在垃圾填埋场处理。

5.0 Summary/总结

A proven low-cost purification system based on absorption resin technology is now available for a variety of pickling acids including the nitric / hydrofluoric mixtures used for stainless steels. In addition to reducing acid purchases and disposal requirements, the continuous system allows pickling baths to be economically operated at higher free acid and lower dissolved metal levels than would normally be considered practical. This

can lead to significant increases in productivity.

已经证实基于吸附树脂技术的低成本纯化现在已经成熟的应用于各种酸洗行业,包括应用在不锈钢行业的硝酸/氢氟酸混酸。除了减少酸的采购和处理成本外,并可经济的实现在更高浓度的游离酸下连续酸洗,并且金属溶解盐度比通常认为是可行的浓度更低。这可以显著的提高生产力。

6.0 References

1. metals Ilandbook, 9th Edition, Volume 5 , pp 7 3 - 7 4 , American Society for metals, metals Park, Ohio

2. M.J. Hatch, J.A. Dillon, Industrial and Engineering Process Design and Development, 2, 4, 253 (1963)

3 . I.H. Spinner, R.F. Hunter, Canadian Journal of Chemical Engineering, 42, 28, (1964)

4 . C . J . Brown, D. Davy, P.J. Simmons, Plating and Surface Finishing, 66, 54 (January 1979)

For Handling, Safety and Storage requirements please refer to the individual Material Safety Data Sheets available at our offices. The data included

herein are based on test information obtained by Thermax Limited. These date are believed to be reliable, but do not imply any warranty or

performance guarantee. Tolerances for characteristics are per BIS/ASTM. We recommend that the user should determine the performance of the

product by testing on his own processing equipment.

For further information, please contact::